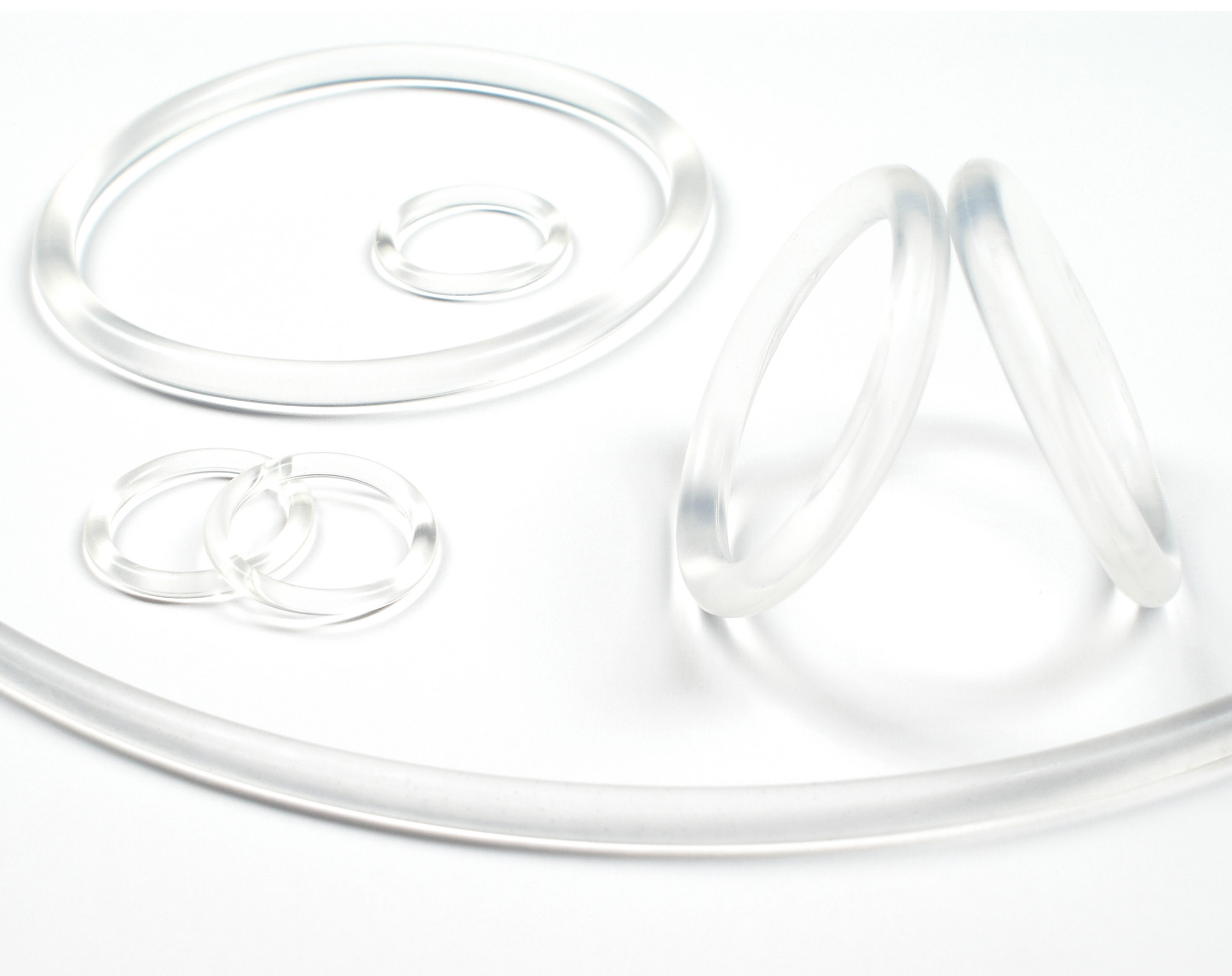

O-Ring Types

Precision Polymer Engineering (PPE) operates and manufactures O-Rings in clean room facilities from United Kingdom or United States. The O-Rings are produced in clean room environment of Class 1000 or Class 10,000 standard.

Factors such as chemicals or gases exposure will affect the integrity of the O-Rings. Therefore, choosing the correct material for O-Rings is important to maximise the expected lifetime.

In order to ensure the best fit, our technical and sales team will first understand your requirements to recommend the most suitable type(s) of O-Ring for your applications.

We will require some information such as:

- Temperature (Minimum / Maximum)

- Length of time exposed to temperature

- Chemicals used in the application

- Type of Seal

- Pressure on the seal

- Application used for semiconductor process

Based on inputs gathered from customers, our technical and sales team will be able to recommend the best material O-Rings suited for our customers’ requirement.

There are different types of O-Ring for various applications across different industries:

Perlast® is a registered trademark of Precision Polymer Engineering Ltd.

| Material Grade | Material Type | Hardness | Min. Temperature | Max. Temperature | Description |

| A90H | FEPM | 93 |

0°C 32°F |

250°C 482°F |

ENDURA, Aflas, oil & sour gas resistant |

| E70Q | EPDM | 75 |

-40°C -40°F |

150°C 302°F |

FDA, USP & 3-A compliant terpolymer EPDM |

| G100XT | FFKM | 64 |

-20°C -4°F |

275°C 527°F |

Perlast perfluoroelastomer, ultra-pure semicon grade |

| G65HP | FFKM | 66 |

-15°C 5°F |

275°C 527°F |

Perlast perfluoroelastomer, radical plasma resistant |

| G67G | FFKM | 68 |

-15°C 5°F |

300°C 572°F |

Perlast perfluoroelastomer, plasma resistant |

| G67P | FFKM | 65 |

-15°C 5°F |

275°C 527°F |

Perlast perfluoroelastomer, high purity grade |

| G70H | FFKM | 70 |

-15°C 5°F |

310°C 590°F |

Perlast perfluoroelastomer, high temperature grade |

| G71H | FFKM | 70 |

-15°C 5°F |

310°C 590°F |

Perlast perfluoroelastomer, PTFE grade |

| G74P | FFKM | 74 |

-15°C 5°F |

275°C 527°F |

Perlast perfluoroelastomer, high purity grade |

| G74S | FFKM | 71 |

-15°C 5°F |

260°C 500°F |

Perlast perfluoroelastomer, FDA, USP & 3-A compliant grade |

| G75B | FFKM | 78 |

-15°C 5°F |

325°C 617°F |

Perlast perfluoroelastomer, high temperature grade |

| G75H | FFKM | 74 |

-15°C 5°F |

320°C 608°F |

Perlast perfluoroelastomer, high temperature grade |

| G76W | FFKM | 70 |

-15°C 5°F |

260°C 500°F |

Perlast perfluoroelastomer, chem. resistant grade |

| G7HA | FFKM | 66 |

-15°C 5°F |

310 (°C) 590 (°F) |

Perlast Helios (perfluoroelastomer) high temperature, plasma resistant grade |

| G90DM | FFKM | 90 |

-15°C 5°F |

300°C 572°F |

Perlast perfluoroelastomer, dissipative grade |

| G90LT | FFKM | 90 |

-46°C -51°F |

240°C 464°F |

Perlast ICE perfluoroelastomer, ED resistant, low temp grade |

| G92E | FFKM | 90 |

-15°C 5°F |

260 (°C) 500 (°F) |

Perlast, ED resistant perfluoroelastomer |

| K13X | FFKM | 79 |

-15°C 5°F |

280°C 536°F |

Kimura high performance elastomer |

| K23X | FFKM | 70 |

-15°C 5°F |

270°C 518°F |

Kimura high performance elastomer |

| K2CD | FFKM | 67 |

-15°C 5°F |

300°C 572°F |

Kimura high performance elastomer |

| N70F | NBR | 70 |

-40°C -40°F |

121°C 248°F |

FDA & 3-A compliant copolymer nitrile |

| S70H | VMQ | 75 |

-60°C -76°F |

250°C 482°F |

FDA & USP compliant silicone |

| S71U | VMQ | 75 |

-60°C -76°F |

200°C 392°F |

FDA & USP compliant, platinum-cured, silicone |

| S80U | VMQ | 78 |

-60°C -76°F |

200°C 392°F |

FDA, USP & 3-A compliant, platinum-cured, silicone |

| V70H | FKM | 72 |

-20°C -4°F |

200°C 392°F |

FDA, USP & 3-A compliant fluoroelastomer, copolymer |

| V70Q | FKM | 70 |

-20°C -4°F |

200°C 392°F |

FDA compliant fluoroelastomer, copolymer |

| V70SW | FKM | 70 |

-10°C 14°F |

200°C 392°F |

Steam resistant, FDA, USP, 3-A compliant fluoroelastomer, terpolymer |

| V75G | FKM | 71 |

-20°C -4°F |

200°C 392°F |

Oil & fuel resistant fluoroelastomer, copolymer, green |

| V75J | FKM | 75 |

-20°C -4°F |

200°C 392°F |

Steam resistant fluoroelastomer, terpolymer |

| V75SC | FKM | 74 |

-15°C 5°F |

250°C 482°F |

High fluorine fluoroelastomer with enhanced thermal & chemical resistance |

| V75SR | FKM | 71 |

-10°C 14°F |

200°C 392°F |

FDA, USP & 3-A compliant, steam resistant, fluoroelastomer, terpolymer |

| V75W | FKM | 75 |

-20°C -4°F |

200°C 392°F |

FDA, USP, 3-A compliant fluoroelastomer, copolymer |

| V91A | FKM | 90 |

-51°C -60°F |

225°C 437°F |

EnDura, low temp, ED resistant, terpolymer |

| V91J | FKM | 90 |

-17°C -1°F |

225°C 437°F |

EnDura, excellent strength, high pressure & ED resistant, terpolymer |

| V91K | FKM | 90 |

-41°C -42°F |

225°C 437°F |

EnDura, good all round properties, ED resistant, terpolymer |

| XE7H | EPDM | 75 |

-40°C -40°F |

150°C 302°F |

Detectaseal, FDA compliant, metal detectable, terpolymer EPDM |

| XN7A | NBR | 70 |

-40°C -40°F |

120°C 248°F |

Detectaseal, FDA compliant, metal detectable, NBR |

| XN7H | NBR | 70 |

-40°C -40°F |

120°C 248°F |

Detectaseal, FDA compliant, metal detectable, NBR |

| XS7H | VMQ | 75 |

-60 (°C) -76 (°F) |

200 (°C) 392 (°F) |

Detectaseal, FDA & USP compliant, metal detectable, silicone |

| XV7A | FKM | 70 |

-20°C -4°F |

200°C 392°F |

Detectaseal, FDA compliant, metal detectable, copolymer fluoroelastomer |

| Y75G | FFKM | 73 |

-15°C 5°F |

260°C 500°F |

Nanofluor, high purity, plasma resistant fluoroelastomer |

| Y75N | FFKM | 67 |

-20°C -4°F |

180°C 356°F |

Nanofluor, ultra-pure fluoropolymer grade |

| Z83B | HNBR | 80 |

-30°C -22°F |

180°C 356°F |

M.O.D. approved NES337 HNBR |

| Z90LT | HNBR | 87 |

-55°C -67°F |

160°C 320°F |

EnDura, Low temperature HNBR |

| Z95X | HNBR | 89 |

-29°C -20°F |

180°C 356°F |

EnDura, high pressure & ED resistant, med ACN, HNBR |

Please contact us if you need any advice from our technical and sales team regarding the types of O-Ring for your requirement. Our technical and sales team will be happy to assist you.

Precision Polymer Engineering

Read on to learn why Precision Polymer Engineering (PPE) is trusted for high performance elastomer seals and components for critical applications.