Integrated Flow Controller

Entegris InVue® Flow Controller Model 6510 & 6520

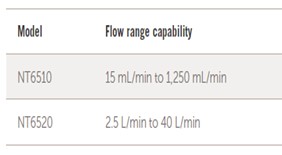

The Entegris InVue® Integrated Flow Controllers (IFC) NT6510 and NT6520 are designed for precise point-of-use chemical flow control in high purity applications. NT6510 is for applications requiring low to medium flow rates, and is the smallest InVue® IFC available, saving valuable space in liquid handling systems. NT6520 is engineered for applications requiring medium to high flow rates.

The user provides a setpoint signal that corresponds to the desired amount of flow. The InVue® IFC compares the setpoint to the actual flow signal from the flow module. If the actual flow is greater than the setpoint, the unit closes the valve. If the actual flow is less than the setpoint, the unit opens the valve. The flow controller does this in a precise manner until the actual flow signal is equal to the setpoint.

The accuracy of the analog flow measurement is ±1% of full scale flow for the operating range and the operating pressure range is from 10 to 60psig.

The InVue® IFC may be ordered as a continuous type controller or a batch type controller.

The continuous controller type is for applications requiring continuous flow (trickle flow), where the integral valve module is never required to fully close. Typically, another valve is used in conjunction to stop the liquid flow.

The batch controller type is for flow rate control where the integral valve module will fully close between batch dispense cycles.

The IFC may be mounted in any orientation without any loss of performance.

Contact us today to find out more about Entegris Integrated Flow Controllers.